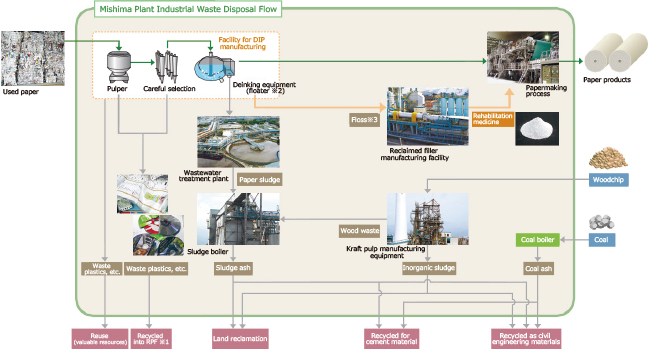

Realize zero waste emission

Daio Paper strives for Zero Waste Emissions via the cyclical use of waste generated through the production of pulp and paper, for applications in cement materials, construction materials, land reclamation, and others.

Waste materials such as waste plastics discharged from the pulper and during the screening process of deinked pulp production are recycled into RPF*1, a type of fuel. Ink is removed from recovered paper using flotation equipment*2, and the residue froth*3 is recovered as inorganic chemicals (recycled filler) to be used in the papermaking process.

※1 RPF [Refuse Paper & Plastic Fuel]

Solid fuel made from non-reusable waste paper and waste plastics among industrial waste. Because of its high calorific value, it is used in many industries such as papermaking and steel as a substitute for fossil fuels such as coal and heavy oil.

※2 Flotation equipment

A device that washes and removes ink printed on recovered paper with chemicals (detergents) to release and reclaim paper fibers (pulp).

※3 Froth

Removed ink components and fine fibers and inorganic chemicals contained in the foam generated by the flotation equipment.

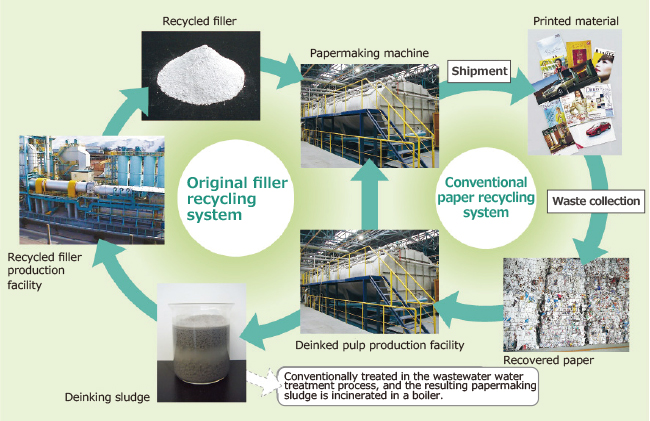

Recycling of Paper Resources

Daio Paper strives to reduce waste materials and conserve natural resources by making use of a filler recycling technology that it put to practical use ahead of other companies

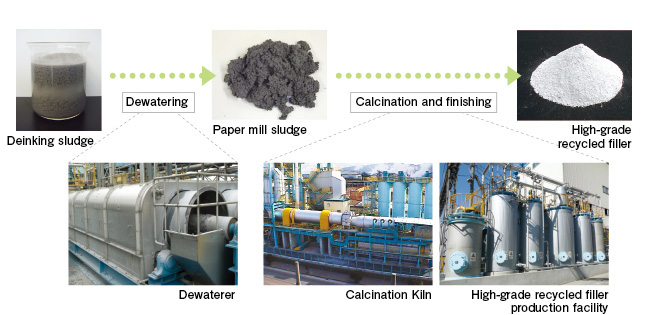

In general, deinking sludge and inorganic chemicals that are removed as foreign matter during the production of deinked pulp are disposed of as waste. Daio Paper has put to practical use a technology to recycle the inorganic chemicals contained in this type of waste as fillers, and is currently using them in various types of paper, thereby reducing waste.

To Improve the Quality of Recycled Fillers

1.Characteristics of high-grade recycled fillers

High-grade recycled filler is improved by coating the surface with particulate chemicals to makes it easier for oil to be absorbed into the interstices of the particles. When formulated into paper, it captures the oil of printing ink and prevents the oil from soaking through to the other side of the paper, reducing print strike-through (and print show-through) even for thin papers.

In addition, high-grade recycled filler contains a wide variety of minerals such as calcium carbonate and clay, which have different light scattering properties, and by controlling the particle size, it will also improve paper opacity.

2. Benefits of incorporating into paper

By incorporating high-quality recycled filler into newsprint, it will improve paper opacity (reduce print strike-through) and paper flatness (improve ink receptivity), making it possible to reduce the weight of the paper.

Also, by coating the surface of the recycled filler, it reduces the roughness of the surface of the filler. As a result, papermaking fabrics (forming fabrics, etc.) will be less prone to damage, prolonging their lifespan, hence enabling stable operation of the machine.

In addition, since the size of the filler particle is made larger with the coating, the filler is better retained in the paper, hence the amount of the yield enhancer (agent) added is greatly reduced, leading to resource conservation.

Reducing the Amount of Incinerated Effluent Sludge Ash by Recycling Deinking Sludge into Filler

Deinking sludge, a waste product of deinked pulp production, used to end up as effluent sludge after treatment. However, at Daio Paper Mishima Mill, we are reusing deinking sludge by recycling it into filler (chemicals mixed into paper to achieve higher opacity).

Recycled filler production facilities

In order to reduce the amount of effluent sludge generated, we are working to improve the quality of recycled filler and expand the variety of paper we use recycled filler in.

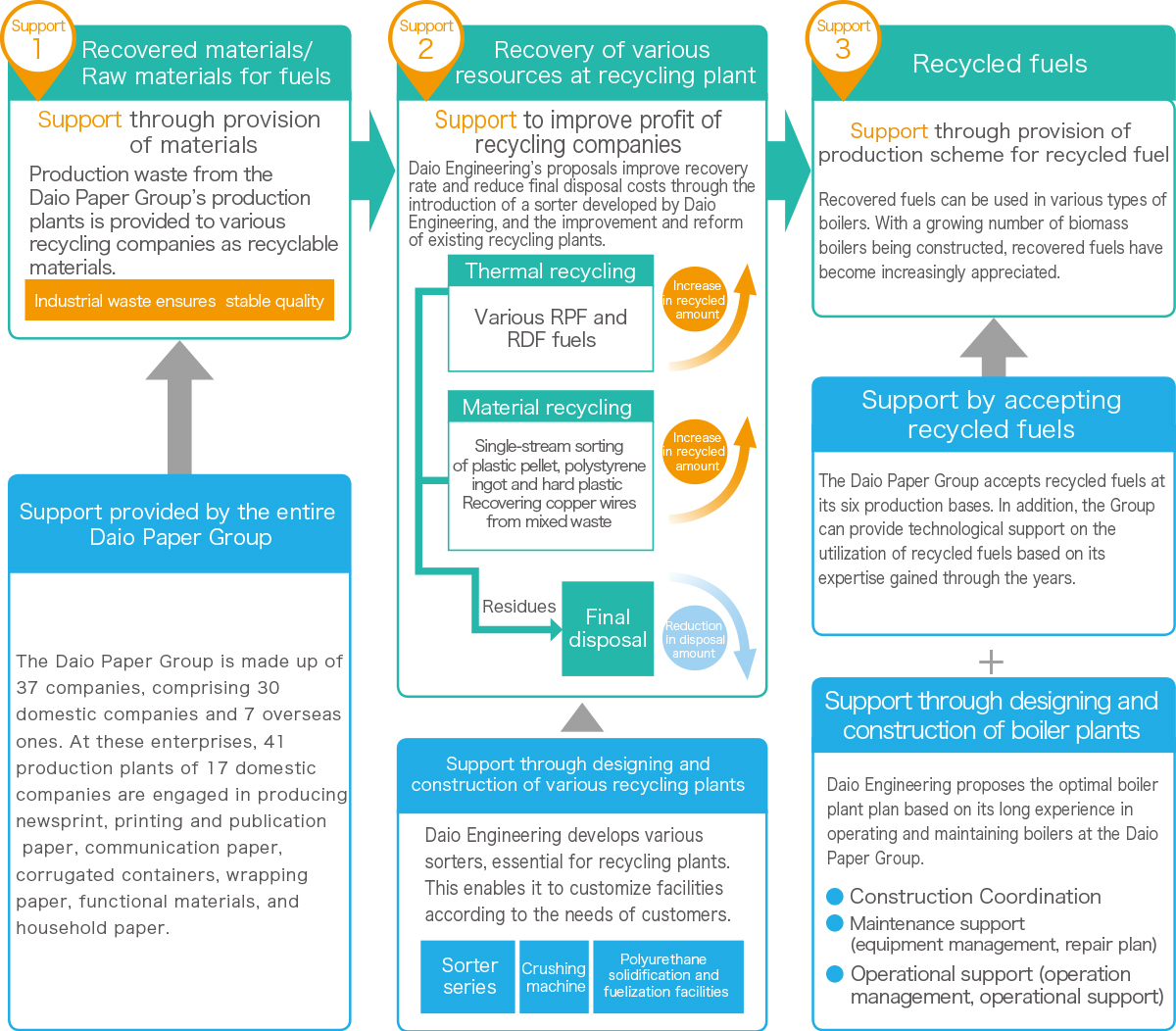

Supporting Environmental Recycling by Converting Industrial Waste into Recovered Fuel

Waste plastics, waste home appliances, and discarded automobiles has been disposed of as industrial waste. However, the Daio Paper Group is promoting the recycling of these materials through the following measures (carried out by Daio Engineering).

1) Propose plant-improvement plans to recycling businesses

2) Design and construct facilities to reduce the volume of waste and convert waste into recovered resources and fuels

3) Improve the recycling rate and reduce the final disposal cost of recycling companies

4) Accept the recovered fuels, such as refuse plastic fuels and heat-insulating materials (polyurethane) of refrigerators, for use at the biomass boilers of the six production bases of the Daio Paper Group

Through the effective utilization of wastes across the group, the Daio Paper Group strives to achieve a sustainable society.

Efforts to reduce the amount of final disposal of industrial waste

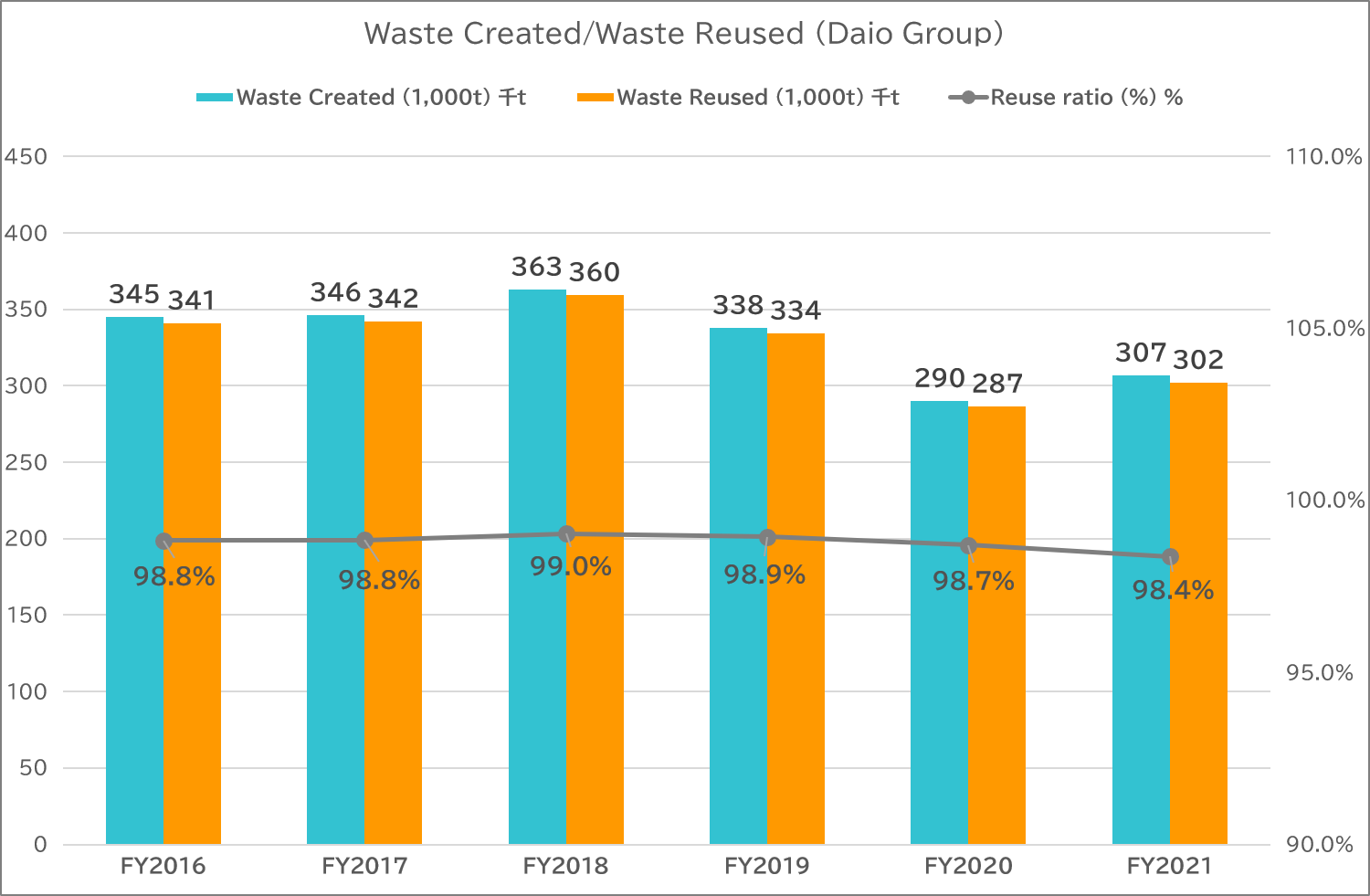

We are working to reduce the final disposal amount (landfill) by switching the industrial waste generated by the Daio Group to an intermediate treatment company for recycling. In fiscal 2020, the final disposal amount for the entire group was approximately 3,000 tons (1.3% of the total).

Initiatives for Recycling Waste Materials

Industrial waste such as ash generated from incinerating sludge from effluent treatment, ash generated by biomass boilers, and sludge generated in the chemical manufacturing process have been recycled mainly into cement raw materials and road bed materials. In addition, we have started to recycle industrial waste into concrete blocks, recycled soil, and sub-materials for steelmaking. As a result, excluding the final disposal (landfill disposal) amount of solid waste, we achieved an industrial waste recycling rate of 98.7%.

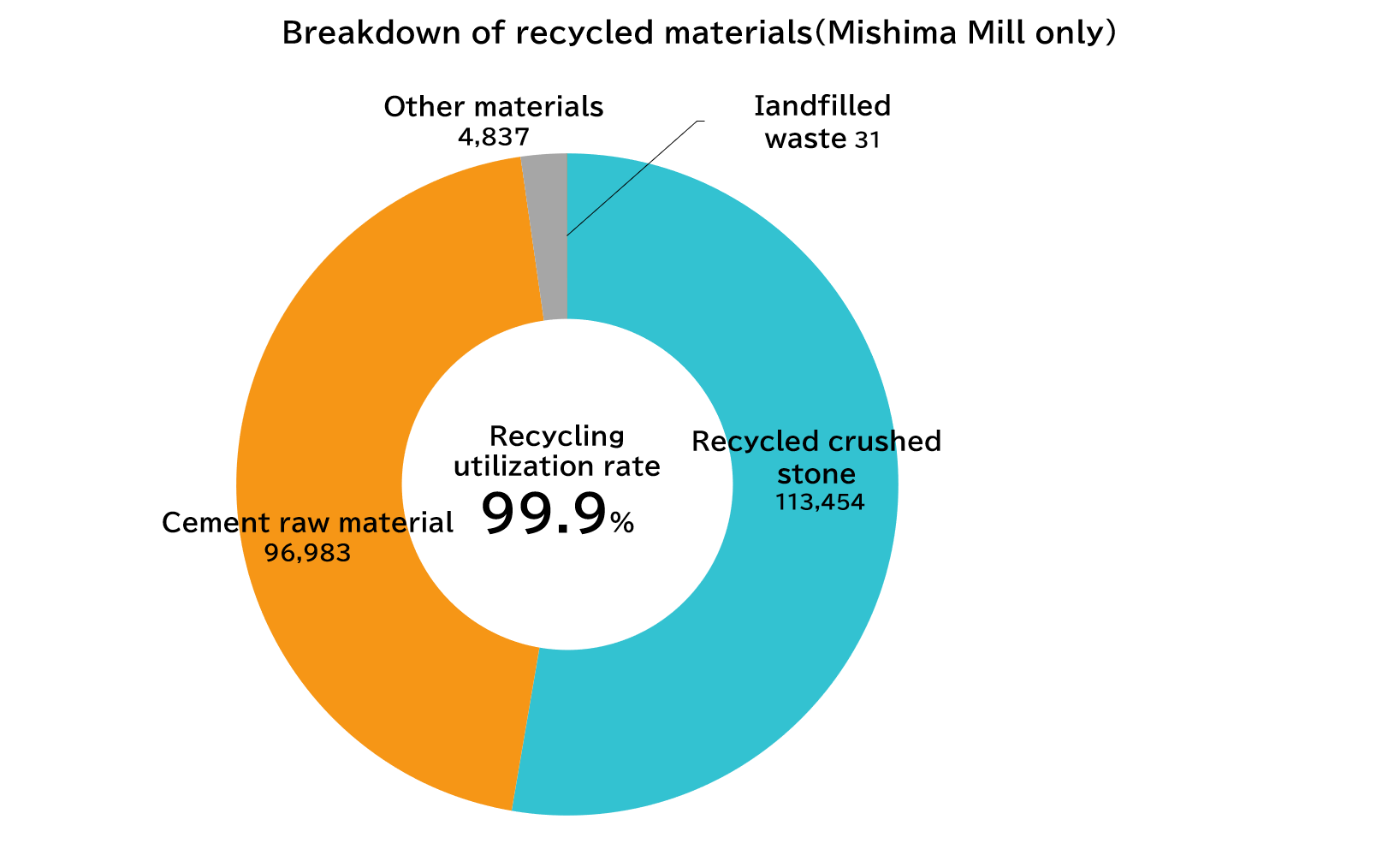

The Mishima Mill accounts for about 72% (251,000 tons) of the total amount of industrial waste generated by the entire group, but we are promoting recycling for recycled crushed stone and cement raw materials, and the recycling rate is 99.9%.

Initiatives for Reducing the Amount of PRTR Substances

The Daio Paper Group gives maximum consideration to product safety by appropriately managing the use of chemicals. We adopt new paper chemicals not just based on their effect on product quality, but also perform in-house evaluations to measure their possible impacts on people and the environment. We also check the safety of chemicals already adopted by requiring the submission of chemical content certificates every year.

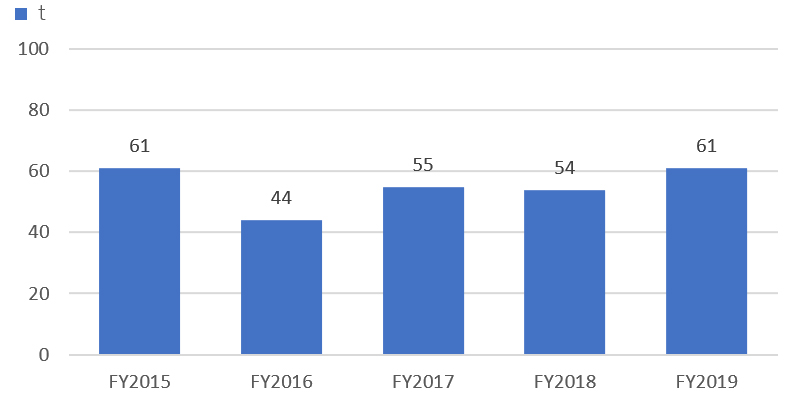

Emission Volume of PRTR-listed Chemical Substances

| Substance No. | Name of Chemical Substance | Unit | Volume Handled |

Emission Volume |

Volume Transferred |

| 1 | Water-soluble zinc compounds | t | 0.6 | ||

| 20 | 2-aminoethanol | t | 0 | 1.1 | |

| 48 | EPN | t | 0.6 | ||

| 80 | Xylene | t | 1.5 | 0.0 | 0.0 |

| 87 | The chloroand compound | t | 0.3 | ||

| 88 | Chromium(VI) compound | t | 0.3 | ||

| 134 | Vinyl acetate | t | 1.1 | 0.1 | 0.0 |

| 144 | Inorganic cyanogen compound | t | 0.3 | ||

| 147 | Benthiocarb | t | 0.1 | ||

| 150 | 1,4-dioxane | t | 0.3 | ||

| 158 | 1,1-Dichloroethylene | t | 0.1 | ||

| 159 | cis-1,2-dichloroethylene | t | 0.2 | ||

| 186 | dichloromethane | t | 0.1 | ||

| 242 | Selenium and the compound | t | 0.1 | ||

| 243 | Dioxins | g-TEQ | 6.2 | 0.1 | 6.5 |

| 262 | tetrachloroethylene | t | 0.1 | ||

| 272 | Copper water soluble salt | t | 0.3 | ||

| 279 | 1,1,1-trichloroethane | t | 1.7 | ||

| 281 | trichloroethylene | t | 0.1 | ||

| 296 | 1,2,4-trimethylbenzen | t | 1.6 | 0.0 | |

| 300 | Toluene | t | 762.9 | 39.4 | 17.8 |

| 305 | Lead compound | t | 0.1 | ||

| 332 | arsenic and the inorganic compound | t | 0.1 | ||

| 374 | Hydrogen fluoride and its water-soluble salt | t | 0.0 | 2.8 | |

| 400 | benzene | t | 0.1 | ||

| 405 | Boron compounds | t | 0.0 | 9.9 | |

| 411 | Formaldehyde | t | 1.3 | 0.7 | |

| 412 | Manganese and its compounds | t | 1.1 | ||

| 438 | Methylnaphthalene | t | 1052.0 | 0.2 | |

| 453 | Molybdenum and the compound | t | 0.1 | 0.1 | |

| 合計 | t | 1820.7 | 60.8 | 17.8 | |

Notes:

1. Scope of data collection: Daio Paper Corporation and the production bases of the Group companies

2. Only chemical substances with 1 t or more of volume handled are listed.

3. Dioxins are excluded from output data aggregation due to differences in units of measure used.