Research and Development

Cellulose NanoFiber (CNF), a wood pulp-derived high performance material, is one-fifth the weight of steel but possesses five times its strength. It holds promise for applications in various fields, including automotive parts, films, filters, and paper. Various companies and research institutions are currently in a race to develop applications for CNF. Daio Paper is working to develop applications and overcome cost barriers toward commercialization of the new material.

Employee Spotlight

He joined Daio Paper in 2009 and has been conducting research and development on CNF at the current Advanced Materials R&D Center for the last five years.

Advanced Materials R&D Center, Production Division

Research and Development Achievements toward Commercialization of CNF

- December 2013

- Started supplying samples of CNF slurry (2% solids content)

- June 2016

- Established and started up a CNF slurry manufacturing pilot plant with a maximum annual production capacity of 100 tons (based on the results of a NEDO assisted project)

- October 2016

- Succeeded in the development of CNF-containing structural composite, and in November, a porous artificial bone graft material (through a joint development project with Fukuyama Ika Co., Ltd. and Chiba Institute of Technology)

- April 2017

- Launched Elleair Kirekira! Nano EX toilet cleaning wipes with CNF content

- July 2017

- Started supplying samples of CNF-containing structural composite

- December 2017

- Established and started up a CNF powder pilot plant with a maximum annual production capacity of 10 tons (through the Ministry of the Environment’s project for low-carbon technologies in the manufacturing process of CNF products)

- March 2018

- Launched a joint research and development project with Sumitomo Mitsui Construction Co., Ltd. toward the practical application of concrete containing CNF

- August 2018

- Succeeded in developing highly transparent CNF through esterification with phosphorous acid

- October 2018

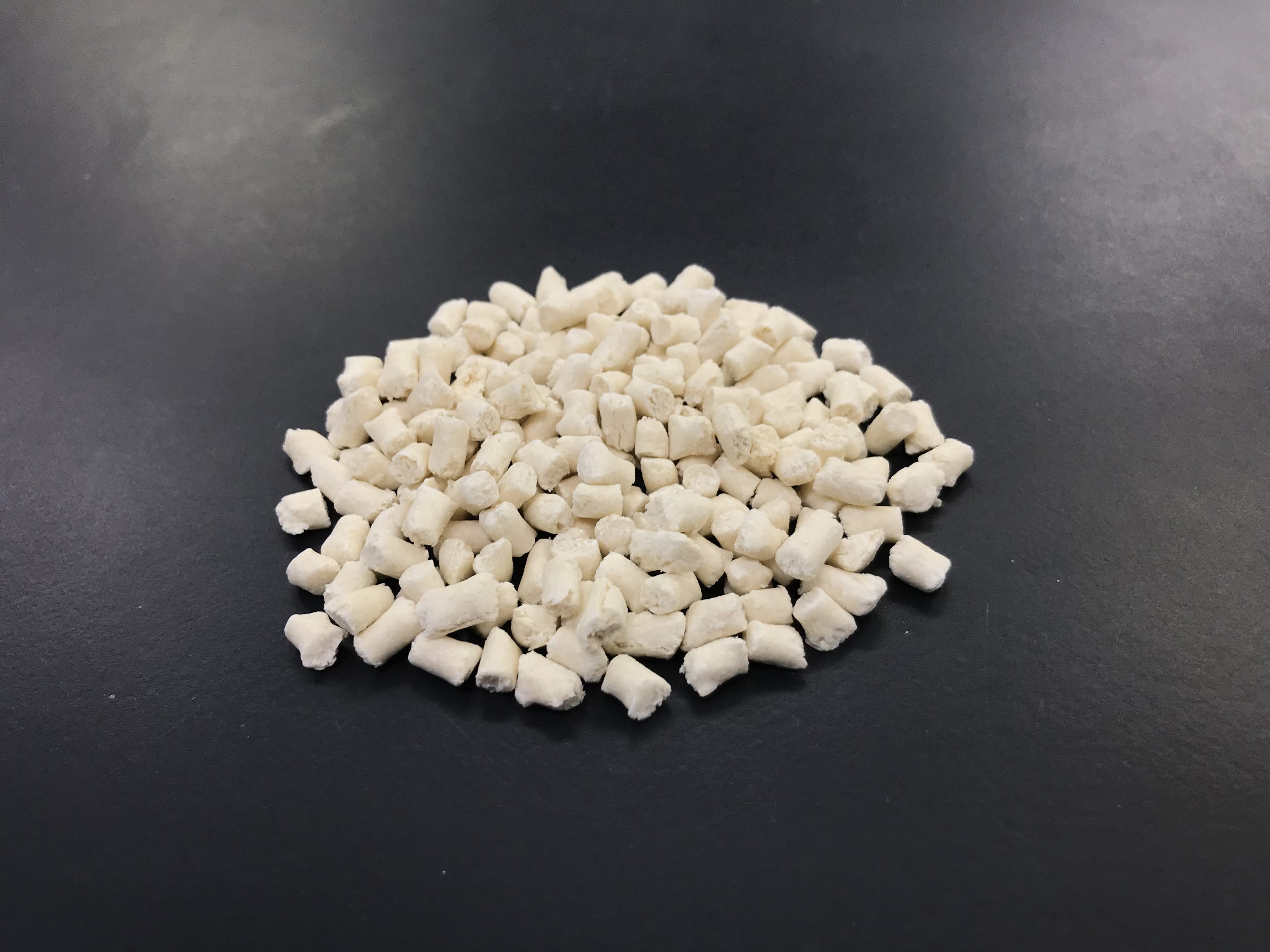

- Began providing samples of cellulose-resin pellets made from a composite of cellulose fiber and polypropylene resin

- June 2019

- Started a joint R&D initiative with Ehime Prefecture to commercialize coatings for ceramic and porcelain products using CNF

- June 2019

- Succeeded in developing ELLEX-M, a high-performance molded CNF material for use in table tennis rackets

- June 2019

- ELLEX-M molded CNF sheets provided to Samurai Speed, an electric vehicle that competes in races in the U.S., and used in the car’s hood, rear doors, and rear spoiler

- August 2019

- Electric vehicle with CNF competes in U.S. race and cuts 16 seconds off its time from the previous year with a car body that is 12.6 kg lighter (49% of parts replaced)

- April 2020

- ELLEX-M molded CNF sheets used as a high-performance material for table tennis rackets

- August 2020

- ELLEX-M molded CNF sheets and ELLEX-R composite CNF-resin pellets provided to SAMURAI SPEED, an electric vehicle that competes in races in the U.S., and used in the car’s hood, rear and side doors, instrument panel (interior), and door mirrors

- August 2020

- Succeeded in developing ELLEX-R55, a CNF-resin composite that has raised the cellulose content to 55%

- May 2021

- ELLEX-M molded CNF sheets and ELLEX-R composite CNF-resin pellets provided to Samurai Speed, an electric vehicle that competes in races in the U.S., and used for the roof and in the front doors, rear doors, and door mirrors

Kirekira! Toilet Cleaner

Revoldia CNF table tennis racket

Recent Research Achievements

- May 2021

- Front bumper for buses using CNF molding material “ELLEX-M” jointly manufactured with Yamasei Corporation.It was installed on the front bumper of a sightseeing bus newly introduced by the Dogo Prince Hotel Group.

Implementation on front bumper

- March 2022

- CNF composite resin pilot plant with an annual capacity of 100 tons (at maximum production) installed and operational

CNF-resin composite

- May 2022

- CNF-added concrete can improve workability during concrete placement by utilizing the characteristic fluidity of CNF in our group headquarters building.

CNF-added concrete

- Jun 2022

- In addition to CNF composite resin and CNF molded products, we provided CNF continuous molded products to Samurai Speed, which participates in U.S. races with electric vehicles, for use in door mirror covers, roof panels, all doors, hoods, and rear spoilers.

- August 2022

- CNF Implementation Electric Car U.S. Race Results: Finished 9th (13:37.568) out of 12 teams in the unlimited modification class.

CNF implemented in electric Car