In order to protect the safety and physical and mental health of our employees, we implement safety educational activities closely related to the workplace.

Occupational Safety and Hygiene Initiatives

We have formulated the Daio Group Safety and Health Activities Policy and engage in safety and health activities on this basis.

Safety and Health System

Our Compliance Committee was established to prevent the risk of major legal violations, ethics violations and other forms of non-compliance that could impact the entire Daio Group. The committee deliberates and decides on policies and specific measures for strengthening the Group’s compliance and risk management systems. It also promotes employee education to raise compliance-related awareness and issues reminders to encourage responsible, ethical action. In addition, a subcommittee has been established to identify and catalog all risks faced by the Group without exception. It deliberates on and promotes specific risk management measures and confirms that they function as an ongoing system, which creates a highly effective risk management system overall.

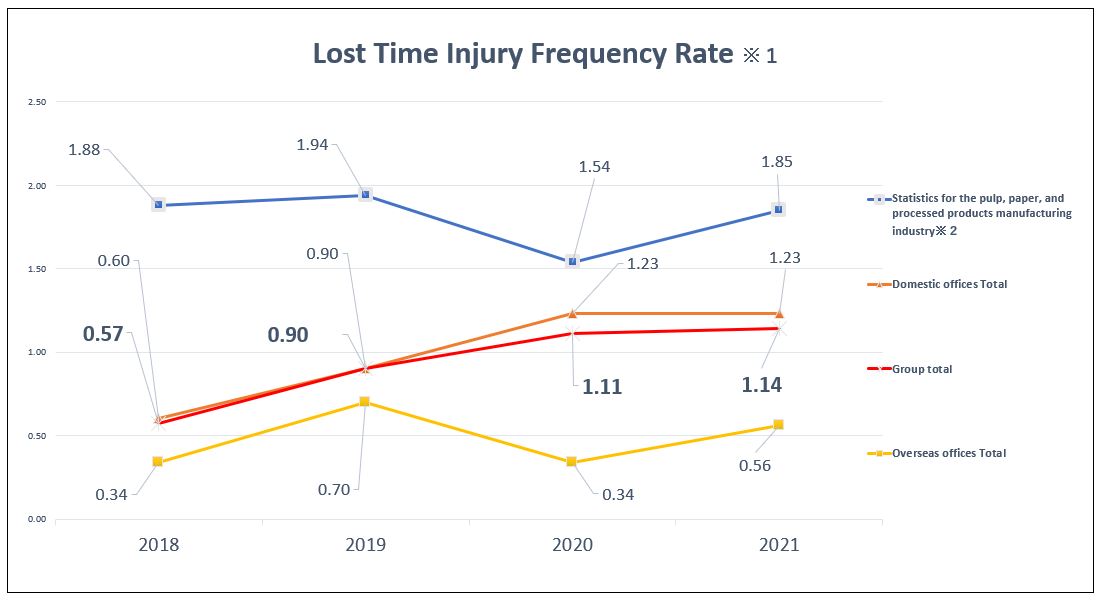

Daio Group’s Safety Achievements

*1 The lost time injury frequency rate is calculated based on the number of injuries and fatalities from a workplace accident causing at least one day of lost work and loss of a part of the body or its function. The figure is the number of injuries and fatalities caused by a workplace accident divided by total actual working hours during the same period multiplied by one million.

*2 Source: Statistics for the pulp, paper, and processed products manufacturing industry (enterprises with at least 100 employees) in the Survey on Industrial Accidents published by the Ministry of Health, Labour and Welfare.

Safety-First Conferences and Safety Improvement via Risk Assessments

Each group company holds a safety-first conference as a rally to achieve zero accidents that result in time off work. The Group works to improve the safety of workplaces to protect the safety of its employees by using risk assessment methods that identify and improve unsafe equipment and work processes that can lead to accidents. Elleair Texel received the Gifu Prefectural Labor Bureau Director’s Encouragement Award for its risk assessment initiatives, such as a company-wide assessment of risks identified by all employees, including operators, and the implementation of necessary safety measures.

Point-and-call exercise carried out by all employees to aim for zero accidents that result in time off work.

Safety-first rally

Hands-On Training to Simulate Dangerous Practices

We conduct hands-on training on dangerous work practices that let employees experience the fear of work accidents so that they will take on the tasks of identifying dangerous areas that could cause accidents, and formulate measures to prevent accidents with machineries and equipments on their own initiative. This training is not only provided for young employees but also supervisors. Using specialized training apparatuses as well as hands-on experience exercises at external organizations, we simulate accidents that are prevalent in the papermaking industry, such as getting caught in paper machines, and also less common accidents such as fall from heights and dust explosions.

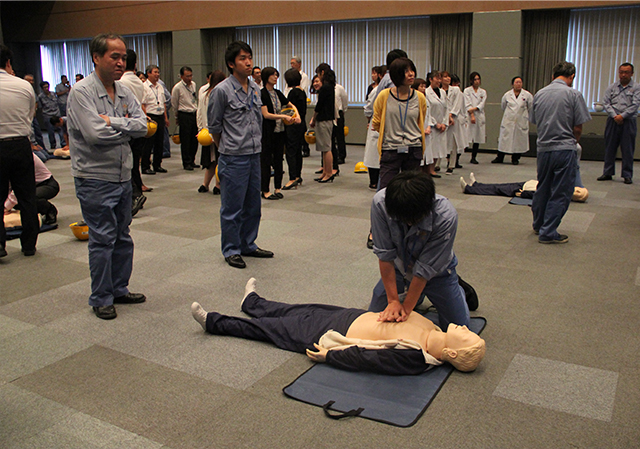

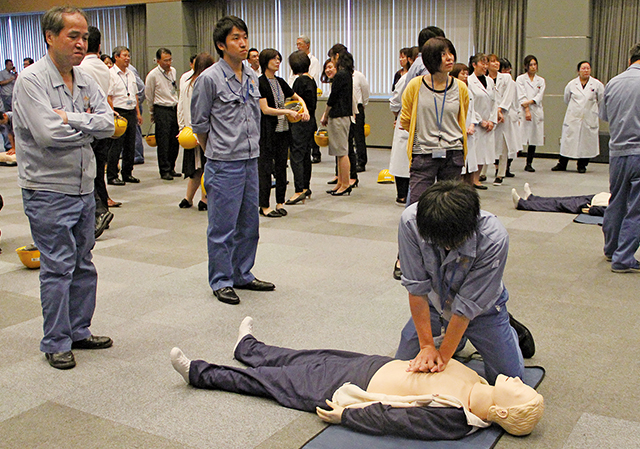

Lifesaving Workshops

Emergency Rescue Drills Using Dummies and AEDs

Fire Department personnels are invited as outside lecturers to hold workshops to train employees to be able to apply the appropriate first aid measures themselves.

They learn how to operate an AED (automated external defibrillator) with a dummy, and how to save lives in pairs. Training on how to protect themselves and their peers in emergencies are also conducted, and at the end of the session, certificates are presented.

Traffic Safety Seminars

For the purpose of raising awareness of traffic accident and violation prevention, we invite Traffic Section managers from the Shikokuchuo Police Station to lecture on traffic safety for employees of the Mishima Mill and the Shikoku Headquarters of Daio Paper, as well as affiliated companies.

Disaster-Prevention Activities

In the event of a large-scale disaster, such as a Nankai-Tonankai earthquake, the Daio Paper Group will designate human life as the top priority and set up a disaster headquarters to confirm the safety of its employees and their family members and identify the extent of damage swiftly. We have designed our business continuity plan (BCP) clearly to ensure there is no discontinuation of important operations concerning stakeholders such as business partners, and to restore normal operations as early as possible even if an operational disruption occurs. We also conduct disaster drills twice a year to enable our employees to respond appropriately and readily.

Basic Policy for Business Continuity Activities

The Daio Paper Group places the highest priority on human life. We will work to fulfill our corporate social responsibility to customers and local communities by recovering the livelihoods of employees and resume business operations at an early date, while preventing secondary disasters, providing support to and cooperating with local communities.

Action Guidelines for Business Continuity Activities

1.Assign the highest priority to securing the safety of human life:

We place top priority on securing the safety of employees and their family members, guests, and visitors above all else.

2.Cooperate to secure safety in local communities:

We provide the utmost cooperation to secure safety in local communities and make efforts to minimize environmental impacts that may arise due to our production plants taking damage from the disaster.

3.Continue important operations:

We designate operations that minimize the impacts of disasters on our customers and local communities as important operations, and prioritize the necessary actions to continue the important operations.

Emergency Drills

The Daio Group regularly conducts disaster prevention drills that is tailored to the locality of each plant. In emergency evacuation drills that simulate the occurrence of large-scale disasters, we conduct training to enable prompt cooperation to prevent the occurrence of secondary disasters in the surrounding areas with top priority placed on ensuring the safety of human lives. In addition, we have formulated a Business Continuity Plan (BCP) so that production can be continued or quickly restored in the event of an earthquake or other emergencies.

Rescue of victims using stretchers

Drill of putting out fire with water from hose

Training to put up fences to prevent heavy oil from spreading out to the sea in the event of an accident

| Name of Mill | Location | Possible Disaster |

|---|---|---|

| Mishima Mill, Daio Paper Corporation | Ehime Prefecture | Nankai Earthquake |

| Kani Mill, Daio Paper Corporation | Gifu Prefecture | Tokai Earthquake |

| Iwaki Daio Paper Corporation | Fukushima Prefecture | Earthquake by Idosawa Fault |

Measures to Prepare for Disasters

Disaster drills at the Mishima Mill

The Daio Group designates September 11 and March 11 every year as Disaster Preparedness Days, and conducts joint disaster drills at the Mishima Mill, the Kani Mill, and the Tokyo Headquarters twice a year. In the joint disaster drills, we mainly conduct reporting drills by using wide-area radio systems and teleconferences to gather information on the extent of damage at each production base and the safety of employees and report to the Tokyo Headquarters.

Disaster Simulation Drills

At these drills, we mainly conduct initial firefighting training in accordance with the disaster-prevention manual, to prevent the occurrence of a secondary disaster in the wake of an earthquake. We also use this opportunity to practice how to use AED and give artificial respiration so that our employees can put the knowledge into practice anytime.

AED training