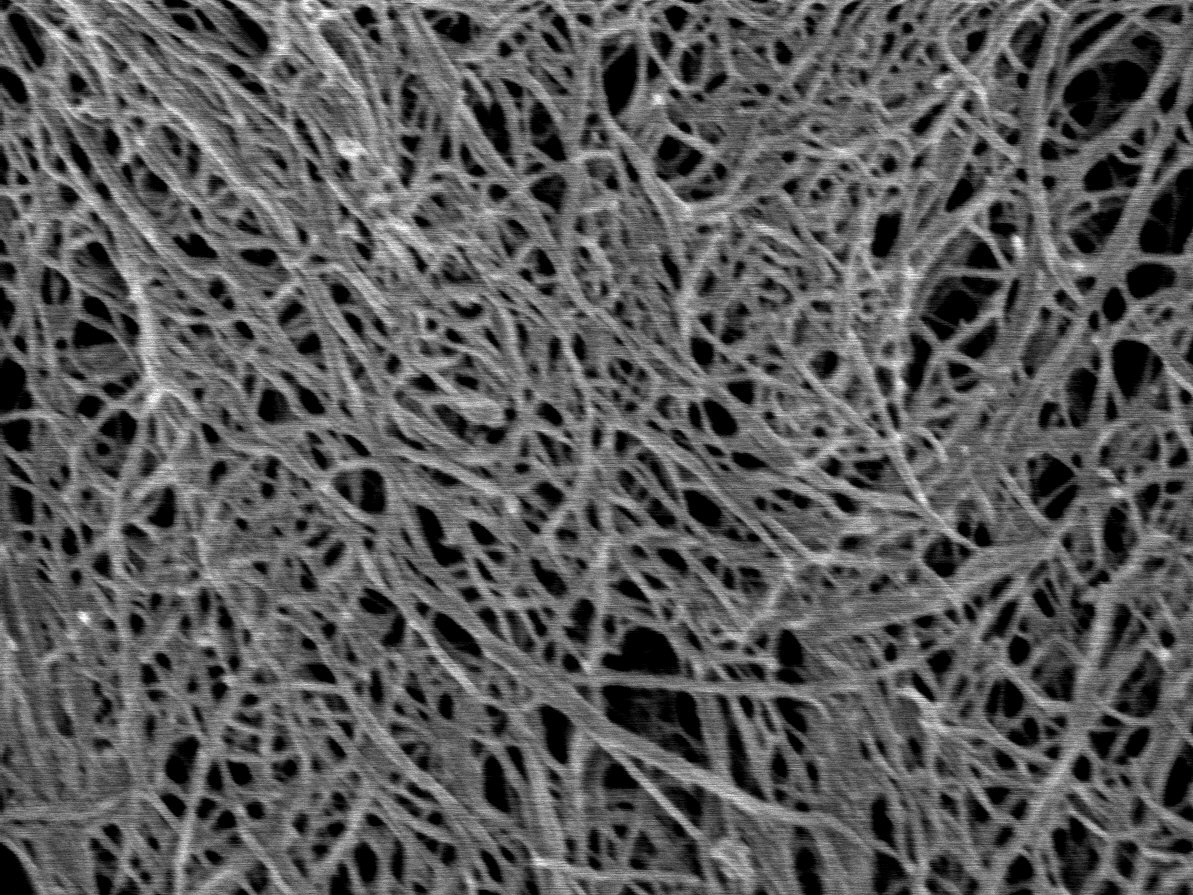

Cellulose NanoFiber (CNF)

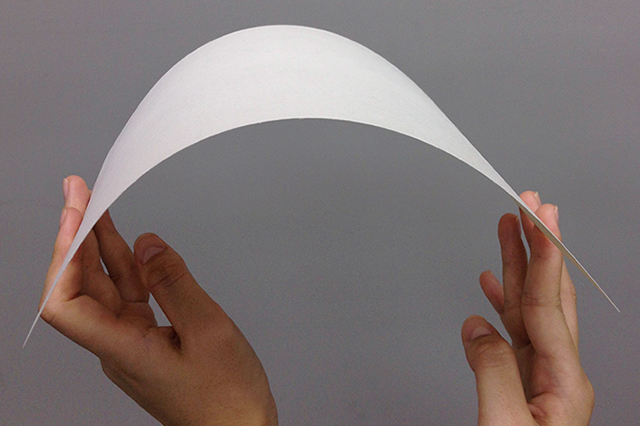

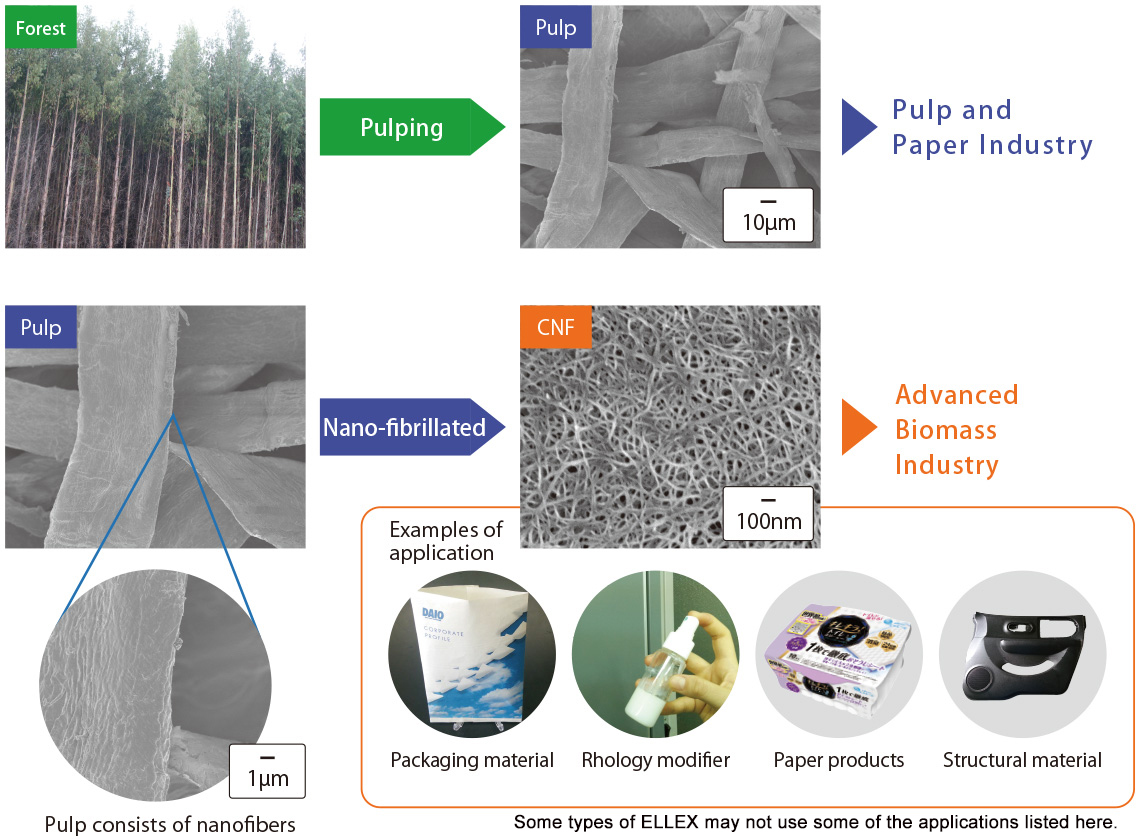

What Is Cellulose NanoFiber (CNF)?

Leveraging their unique properties, CNF is expected to be used in a wide variety of applications. As CNF is a biomass fiber made from trees, it will contribute to the realization of a low-carbon society.

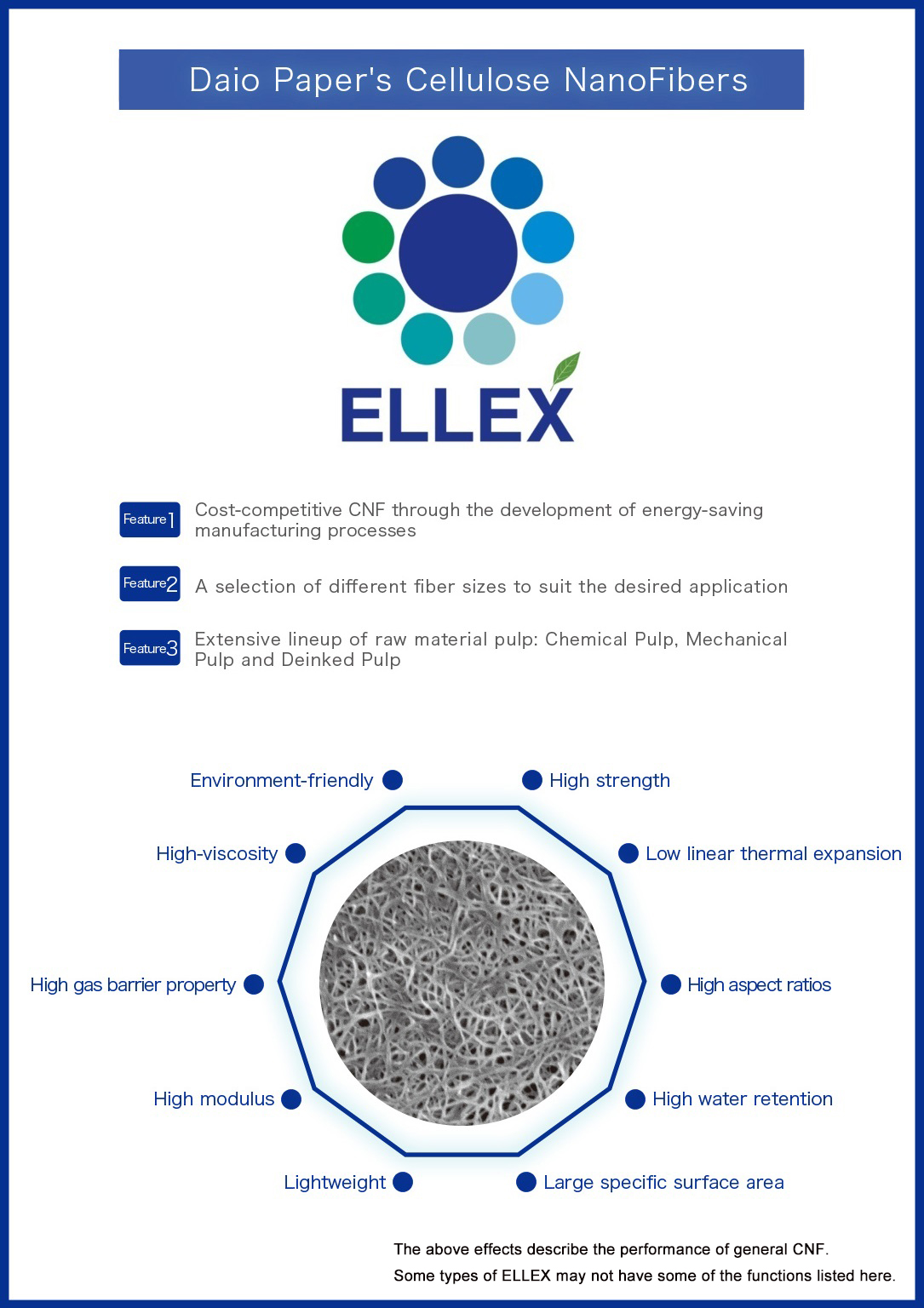

Characteristics of Daio Paper’s CNF

- 1 Cost-competitive CNF through the development of energy-saving manufacturing processes

- 2 A selection of different fiber sizes to suit the desired application

- 3 Extensive lineup of raw material pulp: Chemical Pulp, Mechanical Pulp and Deinked Pulp

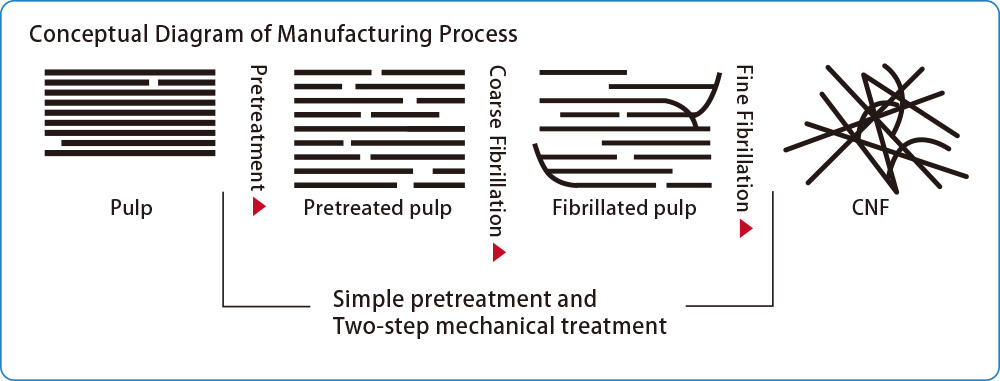

Manufacturing Process

※This is based on results obtained from a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO).

Types of CNF

We have developed our CNF in three forms: aqueous dispersion (slurry), dry powder, and molded sheet. We also have samples of cellulose-fiber-containing composite resin pellets that use coarse fibrillated pulp.

Aqueous Dispersion: ELLEX-S

In order to reduce production costs, we have developed and implemented an energy-saving CNF production process as a pilot plant located at Mishima Mill (Shikokuchuo City, Ehime prefecture) .

Production capacity: Approx. 100 t per year (at maximum production)

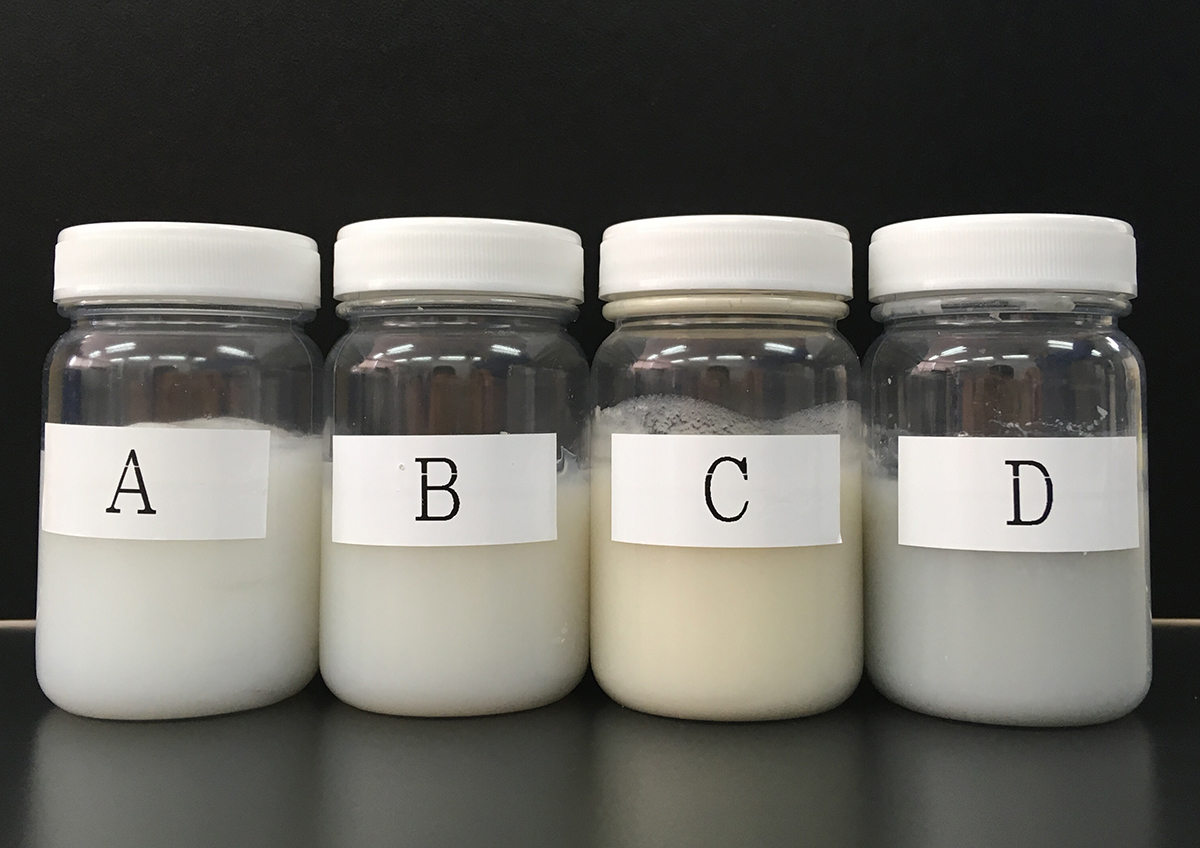

A:Hardwood chemical pulp

B:Softwood chemical pulp

C:Mechanical pulp

D:Deinked pulp

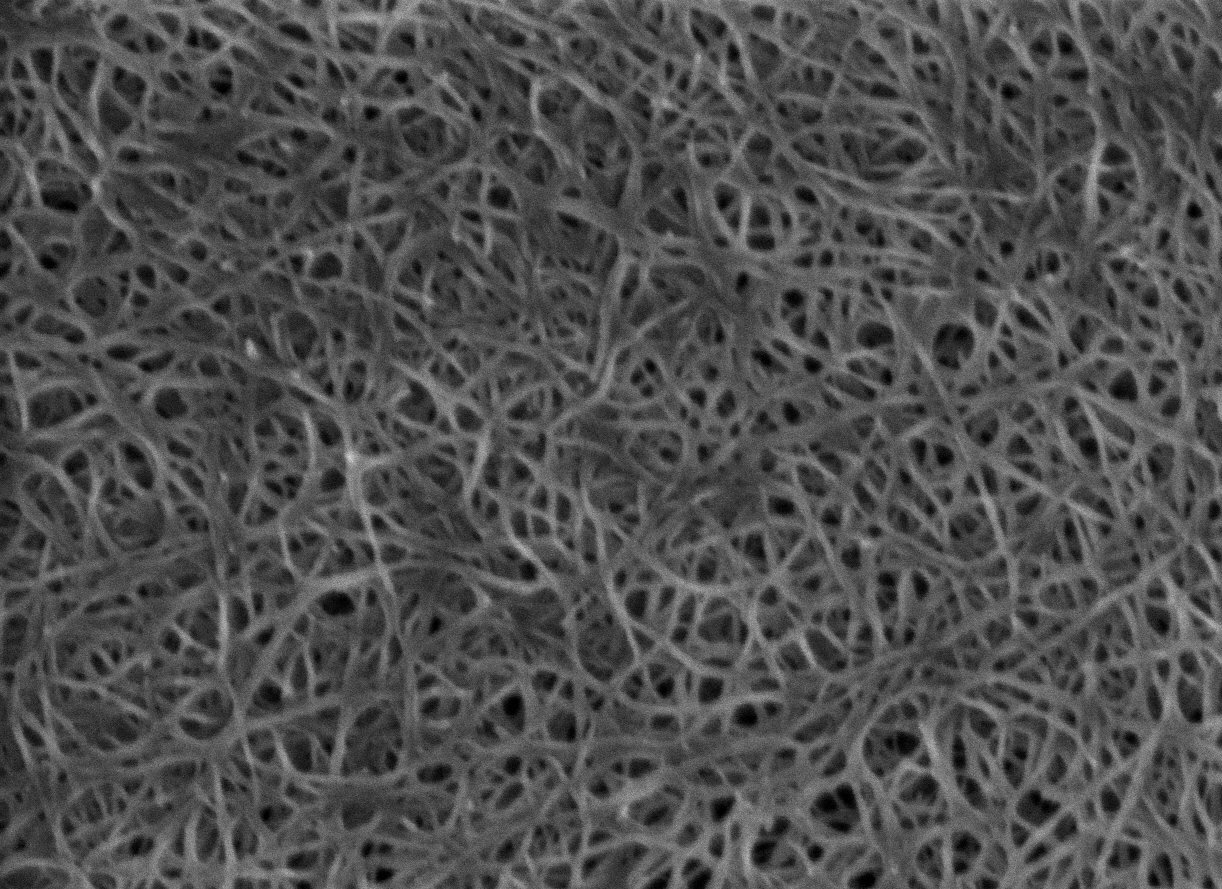

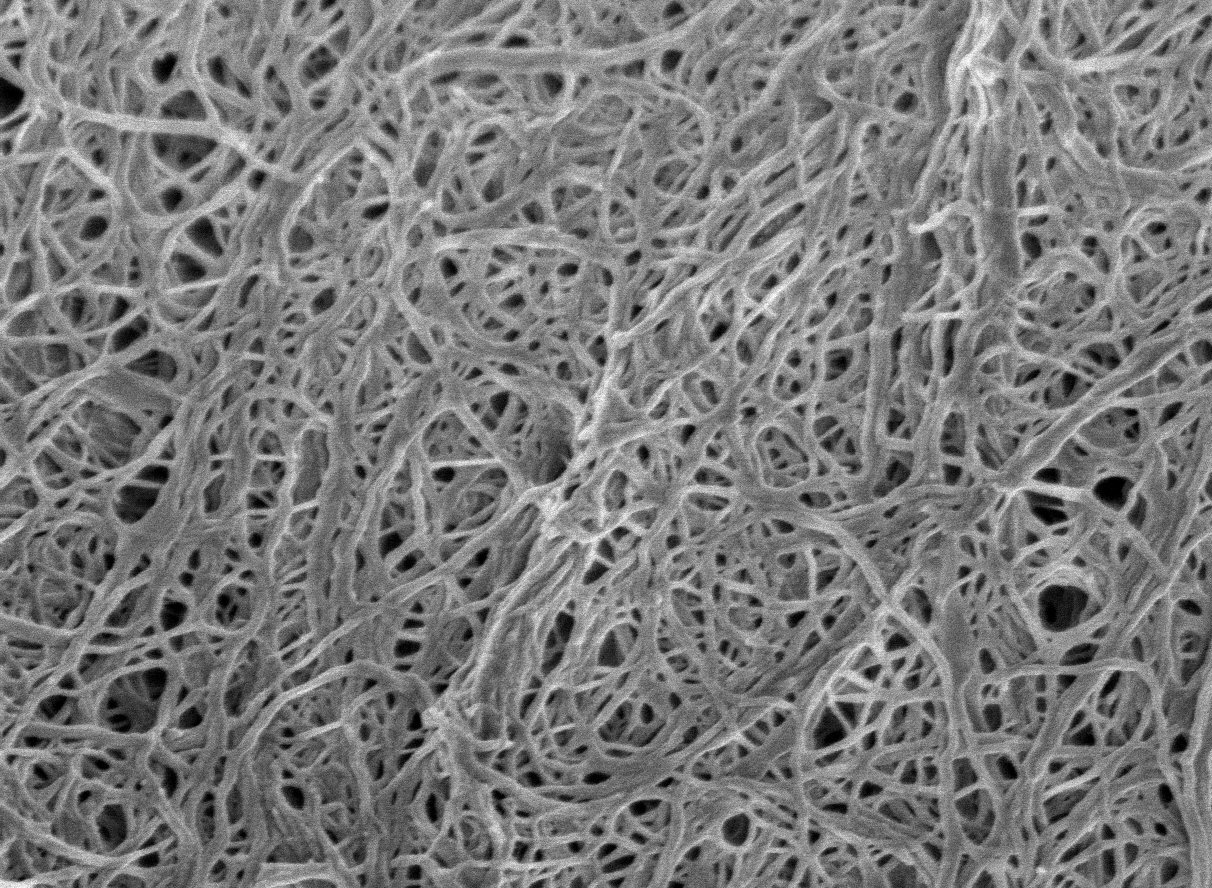

A:Chemical pulp (Hardwood Bleached) B:Chemical pulp (Softwood Bleached) CNF made from chemical pulp. Because of its low lignin content, it has high water retention and good dispersion with hydrophilic materials.

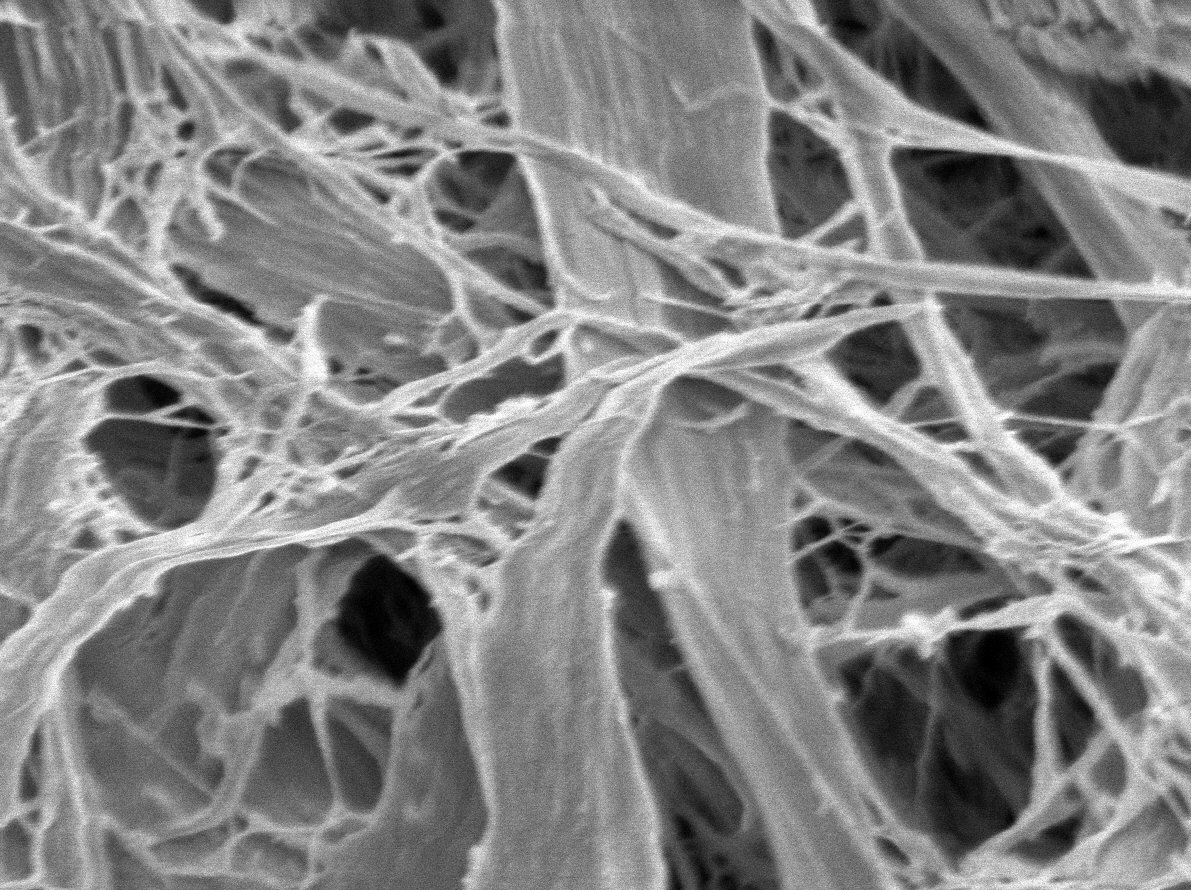

C:Mechanical pulp (Bleached) CNF made from mechanical pulp which is made by grinding woodchips. Because of its high lignin content, it is expected to improve mixing with hydrophobic materials.

D:Deinked pulp (Magazine Deinked Pulp and Bleached) Since CNF derived from old magazine paper contains fine inorganic particles, a reinforcing effect can be expected when compounded with resin.

Dry Powder: ELLEX-P

We have developed a dry powder type of CNF based on requests from many users to solve the difficulties of mixing water-containing materials with resins or rubber.

Production capacity: Approx. 10 t per year (at maximum production)

Molded Sheet: ELLEX-M

A high-CNF-content molded sheet product made from compounding CNF with fiber. This is a high-performance material that takes advantage of CNF’s characteristics of lightweight and high strength. It exhibits mechanical and physical properties that greatly exceed those of general plastic materials, and has excellent thermal properties.